History of Tazen

The Craftsmanship That Captivated Lord Masamune

The history of Tazen in Sendai begins during the Tensho era, a period when Toyotomi Hideyoshi was at the height of his power and glory, flourishing in Osaka. The Tensho era (1573-1592) was a time of remarkable advancement in the fields of art and craftsmanship, leading to the formation of the vibrant Momoyama culture. Zenzo, the founder of Tazen, was also one of the key figures of this Momoyama culture. As a "Mikazari-shoku" — what we would now call a metal engraver — he began to showcase his skills in Tanaka, Osaka.

Now, it was none other than Lord Date Masamune who brought Zenzo, the first generation Tazen, from distant Osaka to the far-off Michinoku region (present-day Tohoku). It seems that each time Lord Masamune traveled to Kyoto under Hideyoshi’s rule, his admiration for Momoyama culture grew stronger. His desire was so intense that during the Bunroku and Keicho campaigns, he discovered Zenzo and convinced him to leave Osaka. This happened in the first year of Keicho (1596). Zenzo left Osaka and arrived at Masamune’s then-residence, Iwadeyama Castle in the Tamatsukuri District. Later, during the construction of Aoba Castle, Zenzo fully demonstrated his skills by decorating the main keep, which greatly pleased Lord Masamune. As a reward for his achievements, Zenzo was appointed as a “Mikazari-shoku,” responsible for creating sword fittings and copper decorations for shrines and temples, and he was granted land in Yanagimachi, where the company is still headquartered today. At this time, although he was a craftsman, Zenzo was also granted the rare privilege of taking a family name. He was given the surname "Tanaka," after his birthplace, and from that moment on, he became known as "Tazen."

Tazen, Loved by Both Lords and Commoners

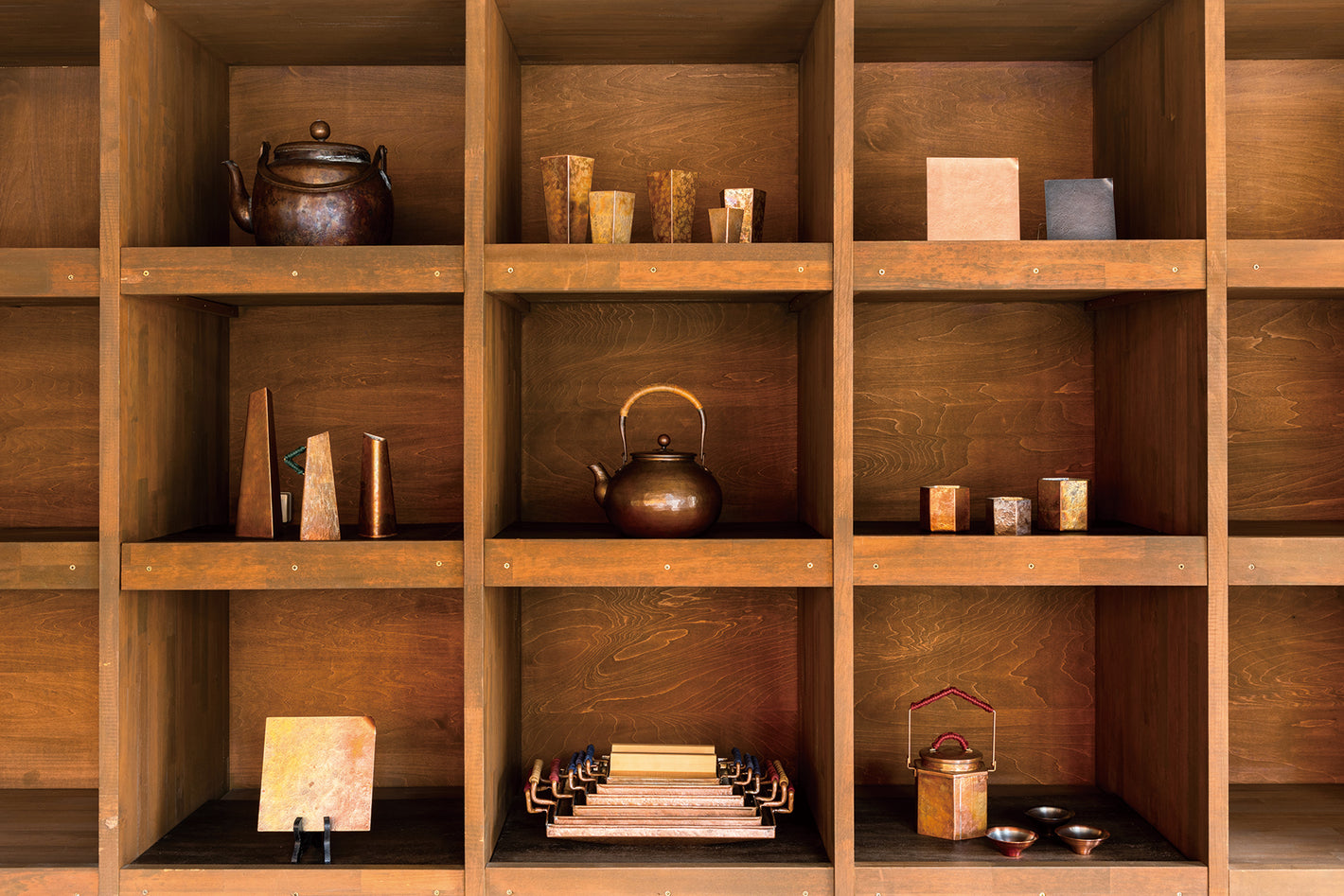

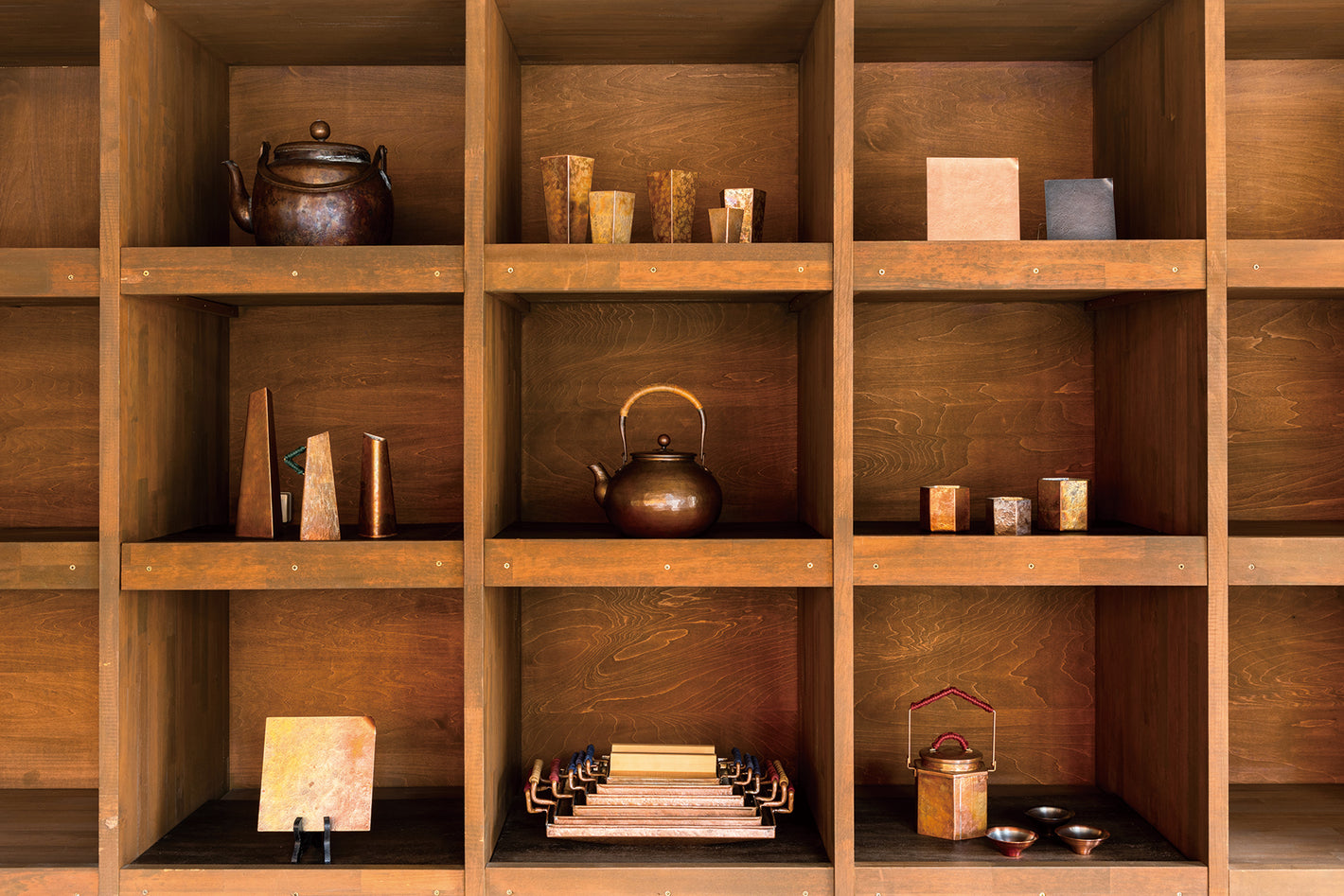

Since the time the first Zenzo established his residence in Yanagimachi, each successive head of Tazen inherited the name "Zenzo" and worked as official metal craftsmen within the Date domain. They specialized in copperwork, creating decorative metal fittings not only for Aoba Castle but also for famous sites like Zuiganji Temple in Matsushima, Osaki Hachiman Shrine, and Zuihoden Mausoleum.

By the time of the fifth and sixth generation, when the world had become more peaceful, most of the work for castles, shrines, and temples had been completed. As a result, Tazen’s work began to intersect more deeply with the everyday lives of common people. During this period, they started producing household goods such as kettles, copper pots (used for heating sake, including household "Sendai-doko" and larger "soba-doko" for commercial use), copper pans, bathtubs for inns and restaurants, and even copper firearms.

The eighth Zenzo made a large copper kettle that could hold about three to (54 liters) and presented it to the Tamura family, who ruled Ichinoseki with a 30,000-koku domain, receiving great praise. Additionally, from the Enpo era (1673–1681), Tazen began crafting tools for confectionery making, such as special pots ("kakemono-nabe") for producing traditional Sendai sweets like "Kokonoe," "Masamune Mame," and "Gojomame," as well as equipment for cooking white anko (sweet bean paste) and other types of anko used in fine confections. As the tea ceremony spread to Sendai and Kyoto-style confectionery shops increased, there was a growing demand for such sweets, and Tazen's copper tools played a key role in this.

To this day, Sendai maintains its traditional confectionery culture, including Sendai dagashi (simple sweets) and Taihaku candy, and Tazen's copper craftsmanship has played a part in sustaining it. In this way, Tazen’s approach of continuously creating what each era demanded, while preserving traditional techniques, earned them the trust of both samurai and townspeople. Whether it was pots, kettles, or steamers, Tazen’s consistent quality in household items ensured that their copper products became an integral part of everyday life.

Flexibly Responding to the Needs of the Times

In 1868, the long era of the samurai came to an end, ushering in the Meiji period. The wave of modernization, known as bunmei kaika (civilization and enlightenment), reached Sendai, leading to the establishment of numerous schools, hospitals, government offices, and hotels, with the Tohoku Imperial University and the Second Army Division being the most prominent. During this great transitional period, the then head of Tazen quickly shifted the business direction. Tazen began focusing on manufacturing kettles for military and school use. In addition, they also ventured into the production of medical, scientific, and chemical instruments made of copper. Following the Sino-Japanese and Russo-Japanese Wars, they exclusively took on the production of copper items ordered by the Second Division of the Imperial Army.

In 1873 (Meiji 6), Tazen surprised the industry by improving the traditional primitive bath boilers and manufacturing boilers for public baths, which garnered attention both within and outside the prefecture. In 1887 (Meiji 20), further improvements led to the development of the "circulating bath boiler," a groundbreaking product developed by the 14th Zenzo, representing cutting-edge technology of the time. As economic conditions improved, other products, such as copper pots for soba (buckwheat noodles), oden pots, and various confectionery tools, also became increasingly popular. It is said that the cooking equipment for making imagawayaki (a popular Japanese sweet) was first developed and manufactured by Tazen during this period.

In the latter half of the Meiji period, the 14th Zenzo decided to abolish the tradition of inheriting the name "Zenzo." From then on, male descendants would only include the character "Zen" in their given names. This decision likely reflected the confidence that Tazen's reputation no longer depended on the inherited name. The 15th head of the family, Zenichi, took over as business entered the Taisho era and continued to prosper. In 1918 (Taisho 7), Tazen manufactured the first gas-powered bath boiler in the Tohoku region, commissioned by the Sendai Gas Company (predecessor of the Sendai City Gas Bureau), and supplied it to the Second Battalion of the Sendai Engineer Corps. Tazen was on a steady path of growth, developing a series of new products.

However, in 1919 (Taisho 8), Tazen was struck by an unexpected disaster: the "Minami-machi Great Fire," which started in the early hours of March 1 in Sendai's Denwa Yokomachi (Minami-machi). The next day's Kahoku Shinpo newspaper reported the devastation, stating that "the flames turned over ten blocks into a lake of fire, filling the air with cries of horror." Yanagimachi, the location of Tazen, was engulfed in flames, and the business was reduced to ashes overnight. The fire caused over 3 million yen in damages, with Tazen suffering losses exceeding 10,000 yen. This blow led the 15th head, Zenichi, to fall ill, and the young Zenji took over as the 16th head of the family.

Zenji, though young, fought hard to restore and rebuild the business. He poured his energy into creating a new version of the circulating bath boiler, modified for cold regions such as Tohoku and Hokkaido. He also introduced new products like the "one-minute sake warmer" and the "Sendai-doko." Additionally, he designed the "shichirin-doko," which used residual cooking heat to heat water, popular among Sendai’s upper-class families and elite restaurants. Thanks to his tireless efforts, Tazen's business not only recovered but also thrived even more than before the fire.

Striving for Post-war Recovery

As Tazen continued to release new products that met increasing demand, the company expanded its operations. In July 1934 (Showa 9), Tazen built a second factory on a 400-square-meter (120-tsubo) plot in Sendai's Hoshun-in Maemachi to accommodate their growing business. However, the bright future was soon overshadowed by dark times. In 1937 (Showa 12), Japan entered the Second Sino-Japanese War, and the escalating conflict brought the enforcement of the National Mobilization Law, which banned the production and sale of copper. This marked the beginning of Tazen’s darkest period.

With no choice but to downsize operations, Tazen was forced to close its newly established second factory. However, the company managed to survive by becoming a designated supplier for the military, focusing on manufacturing soldering irons and producing and repairing medical and scientific instruments. Despite the hardships of wartime, Tazen maintained a small but steady business.

A critical blow to Tazen came on the night of July 10, 1945, during the Sendai Air Raid. The U.S. B-29 bombers reduced the city to ashes, with approximately 57,000 people losing their homes. The area around Yanagimachi, where Tazen was located, was also engulfed in flames, and the company lost everything. Yet, rising from the ashes once more, the 16th head of the family, Zenji, along with his sons Zenjiro (20 years old at the time) and Zenbi (18 years old, later to become executive director, who passed away in 1994), took on the challenge of rebuilding the business. Having already overcome the Great Fire of Sendai, Zenji encouraged his two sons to persevere through this new ordeal.

Focusing on their remaining factory in Hoshun-in Maemachi, Tazen worked tirelessly on its recovery, despite the post-war chaos and difficulties in obtaining raw materials. Tin they dug up and lead pipes from water systems became materials for solder. Zenjiro and his brother resorted to casting on the streets and collecting scrap metal, including burnt tin and iron, to make products like kettles, buckets, and well pulleys, which they sold door-to-door to sustain the business.

Living in a rented house near Hoshun-in Maemachi and commuting to Yanagimachi, they gradually laid the groundwork for recovery. Finally, in January 1948 (Showa 23), they rebuilt a 20-tsubo (about 66 square meters) shop and factory on the original Yanagimachi site, where the company had been founded by their ancestor Zenzo. Although the new facility was modest compared to its pre-war operations, it was a strong and promising first step towards Tazen’s post-war recovery.

Transformation from a Family Business to a Modern Company

After World War II, the circumstances surrounding Tazen changed significantly. The company’s unique handmade copper products became highly valued as souvenirs by American soldiers stationed in Japan. However, with the outbreak of the Korean War in 1950, copper prices soared to record highs, creating a challenging situation where raw material costs were high while product prices remained low. Despite these difficulties, Tazen received an influx of orders, starting with requests to produce bath kettles for the rebuilding of inns such as Iwamatsu and Abe Kiku inns in Sendai. This led to a surge in orders from inns both within and outside of Miyagi Prefecture, along with the production of kitchenware such as oden pots and chawanmushi steamers.

Around this time, a popular product was a rotating cooking device for making "kaiten-yaki," a modified version of a cooking tool originally developed by the 14th generation of the family during the Meiji period. Ten years after the war, with people's living conditions improving and housing reconstruction progressing, Tazen expanded its production facility by 230 square meters and focused on developing an all-purpose bath kettle, which became widely adopted.

In 1955, Zenjiro, the 16th-generation head of Tazen, passed away, and his son Zenjiro took over as the 17th head, alongside his brother Yoshimi. Together, they dedicated themselves to modernizing the company's operations and expanding its product line. In response to future changes in energy sources, Tazen began promoting gas-powered baths in 1956. The completion of the Sendai Gas Bureau’s Haramachi Plant in 1957 led to Tazen being selected as the first designated gas bath manufacturer. In 1958, they established a production line for gas bath kettles and related products, and in 1960, they built a 630-square-meter headquarters to meet the growing demand.

On April 20, 1960, marking its 365th anniversary, Tazen transitioned from a family business to a corporation, renaming itself Tazen Copperware Co., Ltd. (株式会社田善銅器店). This change was seen as essential for adapting to the post-war economy. Tazen then expanded into new areas such as tile installation, heating and cooling systems, and plumbing, solidifying its reputation as a comprehensive manufacturer of bath-related products. During this period, modern materials like poly-enamel and stainless steel began to be used in bathtubs and kitchen sinks, and Tazen became an authorized agent for major manufacturers, positioning itself as a leading company in the housing-related industry.

Connecting with the Local Community

In the 1960s, Tazen expanded its operations significantly. They constructed a new 210-square-meter kitchen center near their headquarters, which they used to produce items such as oden pots, copper kettles, incinerators, stainless steel sinks, and instant gas water heaters. They also continued to develop as a comprehensive supplier in the "fire and water" sector, including bath products and central heating systems.

Tazen didn't just focus on utility products; they also developed artistic copperware and copper interior decorations, blending traditional craftsmanship with modern aesthetics. On November 8, 1969, they completed the construction of the 1,169-square-meter, three-story Oroshimachi building, where they consolidated their wholesale, warehouse, and production divisions. By April of the following year, they integrated the kitchen center with their existing showroom, which became the "Fire and Water Tazen Showroom," a newly renovated facility.

In 1975, Tazen celebrated its 380th anniversary by contributing a pair of large incense burners, crafted from hammered copper and featuring the Date family crest, to Zuihōden, the mausoleum of Date Masamune. This offering demonstrated that Tazen’s traditional craftsmanship was still alive.

Throughout the late 1970s and 1980s, Tazen continued to grow, opening new stores such as the Aramaki store in 1980 and a flagship store in Ichibancho in 1982. By 1988, they had expanded to Izumi City (now Izumi Ward of Sendai), opening the Izumi store. In 1991, they officially changed their company name to Tazen Co., Ltd. They continued expanding into new regions, opening stores in Izumi Chuo and Sendai Minami, ensuring a strong regional presence across central, north, and south Sendai

-

Learn about Sendai-doko

About Sendai-dokoEach copper pot is a unique, handcrafted piece made individually by Tazen’s copper artisans. Please enjoy the mastery that combines traditional techniques passed down through generations with the sensibilities of modern craftsmen.

-

How to Nurture Your Copper Items

How to Nurture CopperThere is nothing special required for maintaining copper items. Simply using them is the most natural form of care. Here, we will introduce some tips to help you use them for a long time.

-

Try Using Copper Items

Akagane MapWe are introducing copper crafts and copper products made by On-akaganeshi (master coppersmiths) that can be seen around the city of Sendai, as well as delicious restaurants that actually use Sendai-doko.